service

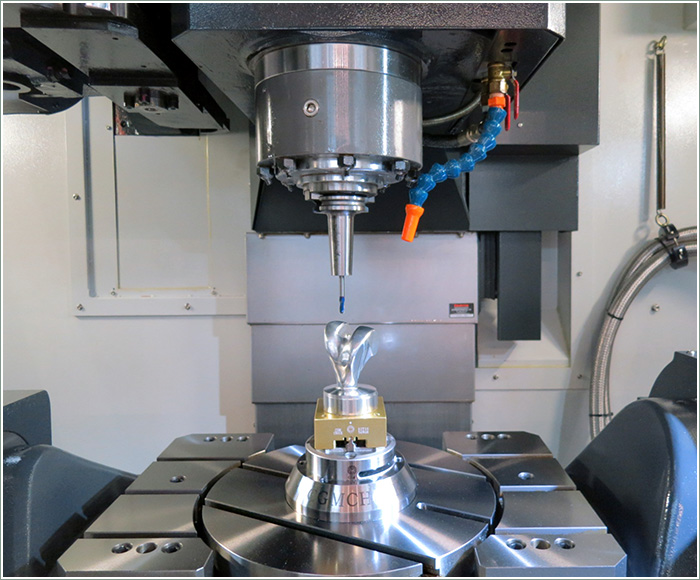

Precsion Processing Service:

CNC machining is currently the mainstream of mechanical processing, we are in the process of CNC machining not only to know what the characteristics of CNC machining, but also know the CNC machining steps, so as to better improve the machining efficiency, so what are the CNC machining steps?

1. Analyze the machining drawings and determine the machining process

According to the processing drawings provided by the customer, the process personnel can analyze the shape, dimensional accuracy, surface roughness, workpiece material, blank type and heat treatment status of the parts, and then select the machine tool and the cutting tool to determine the positioning clamping device, processing method, processing sequence and the size of the cutting amount.In the process of determining the machining process, should fully consider the numerical control machine tool instruction function, give full play to the efficiency of the machine tool, so as to achieve reasonable processing route, less times of cutting and short processing time.

2. Reasonably calculate the coordinate value of tool path

According to the geometric dimension of machining parts and the set programming coordinate system, the movement path of the center of the runaway cutter route is calculated, and all the cutter position data are obtained.General CNC system has the function of linear interpolation and circular interpolation, for relatively simple planar shape parts, such as parts of line and arc contour machining, only need to calculate the geometric elements of starting point and end point, the circular arc of circle (or the circular arc radius), two geometrical element intersection point or tangent point coordinate values.If the nc system has no tool compensation function, the tool center motion path coordinate value is calculated.For parts with complex shapes (such as parts composed of non-circular curves and curved surfaces), it is necessary to approximate the actual curve or curved surface with a straight line segment (or an arc segment), and calculate the coordinate value of its nodes according to the required machining accuracy.

3. Write CNC machining program for parts

According to the parts of the line to calculate the tool trajectory data and determined process parameters and auxiliary action, the programmer can be used in accordance with the numerical control system specified functional instructions and program format, section by section to write the parts of the processing program.At the time of writing, attention should be paid to: first, the writing of the program should be normative and easy to express and communicate;Second, in the use of numerical control machine tool performance and instructions on the basis of full familiarity, each instruction using skills, programming skills

Products ISO9001 Quality Certificate